Plastic Union : fabrikant van 100% recycleerbare verpakkingen

Plastic Union is producent van  polyethyleen verpakkingsfolie voor automatische verpakkingsmachines.

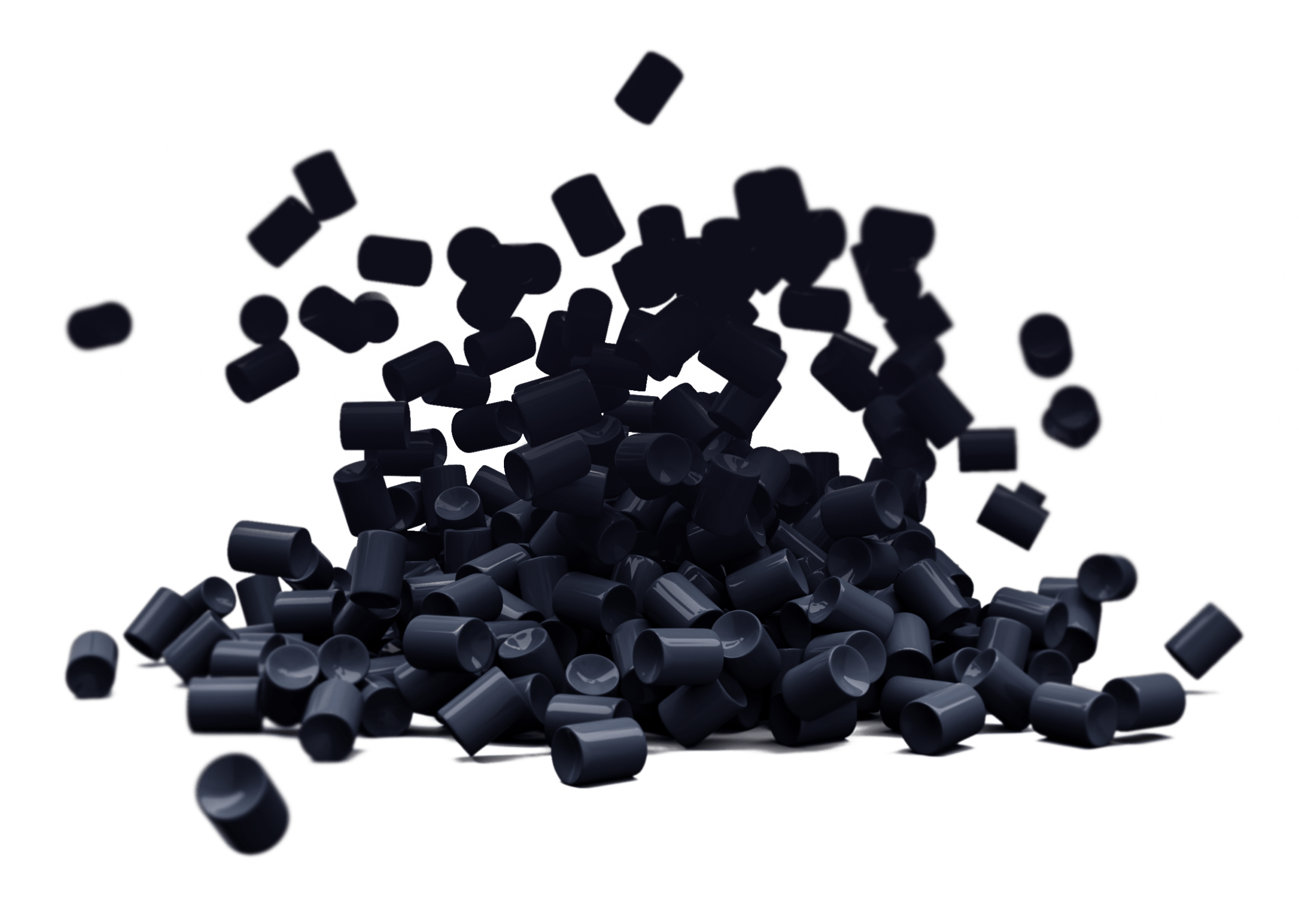

polyethyleen verpakkingsfolie voor automatische verpakkingsmachines.  Het bedrijf is volledig geïntegreerd van korrel tot afgewerkt product en produceert enkel 100% recycleerbare verpakkingen.

Het bedrijf is volledig geïntegreerd van korrel tot afgewerkt product en produceert enkel 100% recycleerbare verpakkingen.  De meeste van haar producten kunnen vervaardigd worden met gerecycleerde of biologische grondstoffen.

De meeste van haar producten kunnen vervaardigd worden met gerecycleerde of biologische grondstoffen.

Productie volgens de wens van de klant

U bepaalt hoe Uw product eruit ziet en wij voeren het uit ! Voor elke toepassing hebben we verschillende kwaliteiten in ons gamma ten einde zoveel mogelijk aan Uw wensen te voldoen. Wilt U vooral een zeer mooie verpakking of liever een zeer sterke verpakking? Of wenst U beiden? Geen probleem we hebben voor U de juiste folie in ons gamma !

InnovatieveVerpakkingen

Stretch Hood

In 2005 starte Plastic Union als eerste belgisch bedrijf met de productie van Stretch hood folie. Inmiddels is Plastic Union uitgegroeid als een van de wereldspelers op gebied van stretch hood folie. Wenst U dat Uw verpakking voldoet aan de Eumos norm? Wij begeleiden U naar de ideale hoes om dit doel te bereiken.

CX-3M Krimpfolie

Zeer sterk, snel lasbaar, snel krimpbaar en glashelder, hierop werd deze folie geoptimaliseerd.

Toepasbaar op alle domeinen en op de meeste verpakkingsmachines.

Dunnere folies zijn goedkopere folies en bovendien betaalt U er minder belastingen op !

PCR en PIR

Om een millieubewuste verpakking te bekomen is het aanwenden van gerecycleerd materiaal de beste keuze. Elke folie die terug in de recyclagemolen belandt, komt niet ter land of ter zee terecht, moet niet opnieuw ontgonnen en geraffineerd worden uit aardolie, maar wordt gewoon opnieuw gebruikt !

PCR staat voor Post Consumer Recycled material, PIR voor Post Industrial Recycled material. Beide opties zijn mogelijk.

BIO-x Folie

Is het gebruik van gerecycleerd materiaal geen optie voor U maar wenst U toch een milleubewuste verpakking ? Dan is de BIO-X folie een oplossing voor U. Deze folies zijn niet van aardolie gemaakt maar zijn wel afkomstig van een hernieuwbare bron. De meeste van onze folies kunnen ook in een BIO versie worden afgeleverd.

200 lpi in flexodruk !

Wenst U het fijnste drukwerk met het meeste contrast om Uw verpakking zo aantrekkelijk mogelijk te maken ? Wij drukken tot 200 lpi in flexo ! Dit is de kwaliteit van heliodruk aan de prijs van flexodruk !

Als fabrikant van recycleerbare plastic verpakkingen is Plastic Union uw partner voor diverse verpakkingen op maat. Gespecialiseerd in ecologische verpakkingen brengt Plastic Union duurzame verpakkingsoplossingen. Zo kan u bij ons terecht voor krimpfolie verpakkingsfolie in grote oplages voor bijvoorbeeld verpakken van flessen en palletten. Onze krimpfolie toepassingen zijn geschikt voor diverse innovatieve verpakkingen. Alsook voor buisfolie in bulk voor diverse verpakkingstoepassingen. Om sterke buisfolie te kopen ben je bij ons aan het goede adres. Ontdek er onder meer ook de vele kwaliteiten van PE folie als verpakkingsmateriaal. Maar u kan er ook plastic zakken kopen in bulk bij Plastic Union, uw groothandel in verpakkingsmaterialen.